Investment: New KOYAMA 500TT XXL

With the evolution of KUHN agricultural machines, but also the demands of external customers, our castings became increasingly voluminous and heavy. These parts exceeded the capacity of some of our grinding machines, which had become too small, forcing us to grind them by hand. Our constant desire to reduce tedious manual operations while improving safety led us to invest in a high-capacity machine, and at the same time to replace the most obsolete machine in our fleet: our ROBAMAT A3.

In service since 1990, our Robamat A3 had largely fulfilled its mission, accepting parts weighing up to 80 kg. In its last years, this machine had become capricious, with excessively long start-up times, repeated breakdowns, and its tooling (workpiece holders) was very worn.

and its tooling (part holders) was very worn. This prompted us to replace the machine, which had become essential, especially as we could no longer find spare parts to keep it in good condition.

With our experience in the field of automated grinding, we had 2 options open to us: a SIR-type robotized cell (robot handling the part in front of the grinding tools) or a KOYAMA cell (part placed on a support which moves towards the grinding tools). We already owned both types of machine, and knew their advantages and disadvantages, which helped us a great deal in our decision.

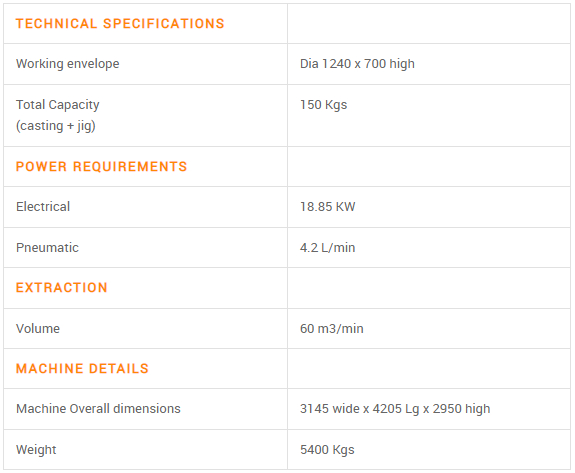

Our choice was a KOYAMA 500 TT XXL

The advantages of such a machine are :

- Its simplicity of use and programming.

- Very simple tooling (to place the parts).

- The fast loading of parts by rotary table with the possibility to put 2 different

to put 2 different references of parts with each its own

grinding program.

- Quick change of type of parts and program.

- Its reliability over time.

- Its efficiency and speed of grinding.

For example, the grinding time of the K841683D scale has been

from 32 minutes when grinding by hand (including handling) to

3.25 minutes (handling is in hidden time).

Delivery / installation